More About This Episode

The Smarter Building Materials Marketing podcast helps industry professionals find better ways to grow leads, sales and outperform the competition. It’s designed to give insights on how to create a results-driven digital marketing strategy for companies of any size.

Vardhan Mehta is co-founder and CEO at Acelab. He talks with Beth about how building materials manufacturers can build better relationships with architects.

Founding Acelab

Vardhan is a second-generation architect. He grew up watching his father (an architect) and uncle (an engineer) grow their practice in India, so it's not surprising that he fell in love with the industry as a child. "I think as a child, what I found the most exciting about this industry was how it's so focused on collaboration. Any project is a team sport, and we all rely on each other," says Vardhan.

He eventually grew up and went to the Pratt Institute in New York before landing a job at one of the city's top 10 architecture firms. As an entry-level junior architect, he handled most of the product research, specification and selection. It bothered him how difficult and time-consuming all of these tasks were. This would eventually lead to the founding of Acelab.

As a junior architect, Vardhan ran into three main problems:

- Information overload

- Waiting until the latest stages of a project before speaking to product manufacturers, so there wasn't enough time to invest in product research

- Access to the right product expert and a manufacturer who can understand your project and the project's location

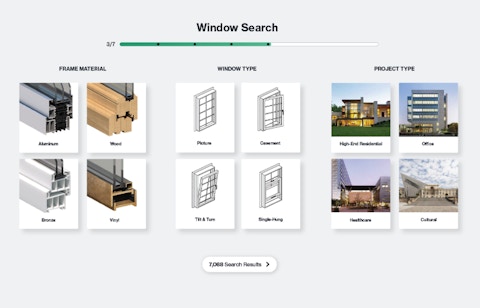

"These are the things that led me to believe that there's a huge opportunity and a lot of value here for both an architect and a manufacturer to start that collaboration in the earliest stages of a project schematic design or design development. And that's where we founded Acelab. The goal was for it to be a visual product selection platform where architects are able to discover, organize and collaborate on product specs all in the same place."

Since its founding, the team at Acelab has discovered an appetite from architects for ongoing education that is more applicable, accessible and easier to understand in a short amount of time. Providing this type of education has become the centerpiece of Acelab's strategy. "We focus on all the content that we make towards architects to be entirely focused on education and for that to be genuinely inherently valuable to them."

The Problem With Building Materials Manufacturers' Websites

Acelab has some tips for building materials manufacturers to improve how they educate and talk to architects about their products.

The biggest challenge Vardhan sees when he reads a manufacturer's copy or he tries to pull information from their website is that the copy isn't written in a way that speaks to an architect.

"If I'm reading a few lines about your products [or] how you have differentiated in the market, at the top, I need to understand what are the project challenges that you will be able to help me overcome with your products and your team of experts. A lot of times, we've had to rewrite a few of the things ... to be more focused towards helping an architect from scratch as opposed to when they first speak to an architect."

The problem is that many websites include a lot of information about "where the company was founded, where it's headquartered, how big the warehouse is, who are the two guys or people who started this company." And while that's great information that you should have, it's not what an architect wants to know when they first come to your website.

Instead, architects are looking for:

- What are the applications of the product?

- Who do I talk to learn more about the product?

- Do you offer free samples?

- Do you have a way for me to get more information without filling out a form on your site?

Vardhan explains that there needs to be "an initial return on value for an architect who's interested to learn more." You've managed to pique their interest — where can they learn more about how you can help them solve a very specific problem on their project?

When to Get Involved

Most manufacturers we talk to firmly believe that they need to be involved at the very beginning of a project. The question is: Do architects believe the same?

Yes, according to Vardhan. It saves the architectural team a lot of rework to try and make the product work in the later stages of DD — assuming they are willing to even rework specs in order to use it. Instead, at that point, they'll use a Frankenstein spec, which is an industry term to describe a recycled spec. These are usually used out of ease and convenience, and without a good understanding of the available options on the market.

So how can manufacturers break through the noise and get an architect's attention?

One way is to partner with a company like Acelab, which was built with a specific toolset to help architects research and choose products. And have all of the information an architect might need on that site. That way, architects can utilize the tools on that site (such as a project workspace and smart search) to find architects.

Then, in the case of Acelab, they can use the collaboration portal to reach out to manufacturers they are interested in. This helps both the architect and manufacturer because the architect gets access to exactly who they need to talk to and the manufacturer gets a warm lead reaching out to them with no cold calling or cold emailing necessary.

Another potentially effective way to build relationships with architecture firms is through lunch and learn. However, there are downsides to this. Many architects might only come for free food. The firm might not have any active projects that are the right fit for your product.

Trade shows, as we've talked about many times on the podcast, are also a great way to build relationships. So long as you're doing it right.

Getting Into the Spec Late

So what do you do as a manufacturer if you've missed the early stages of a project, but that project hasn't reached your product category yet and you want to try and get in the spec? According to Vardhan, getting in the spec at a later stage is still possible these days.

This is mostly due to supply chain issues. "We are also seeing that on Acelab where architects reach out to us all the time where they'll say the project is still in later stages of DD or CD, and the architect will say, 'Hey we have a firm favorite for windows but unfortunately, they're no longer an option because their lead time is right now 26 weeks.''

This opens a great opportunity for manufacturers. If you have a shorter lead time and can help move along a project that's been delayed, let them know, "especially if you can build that trust with architects that you will also be able to support them with your team of experts."

Want Even More Insight?

Today, architects are more interested in and have more agency to choose products that are a healthier alternative. There's a big focus on sustainability, and unlike in the past, architects now have the power to switch manufacturers to get a more sustainable option.

To learn more about building relationships with architects, listen to the entire episode.

If you would like to reach out to Vardhan you can find him on LinkedIn.

Remember to like and subscribe to Smarter Building Materials Marketing wherever you get your podcasts.